A reduction in surgery time and a consistently accurate way to manufacture dentures.

At GoDigital-Dental we recognise that dentures have been manufactured in the same way for most of the last century, the only things that have changed are the materials in manufacture.

Whilst these are now very good the whole process starts with the analogue impression which often the patient can find is uncomfortable and it can also be inaccurate.

In order to eliminate these two negative components of denture manufacture we are now looking to make a denture not only through a digital process but also from a digital impression.

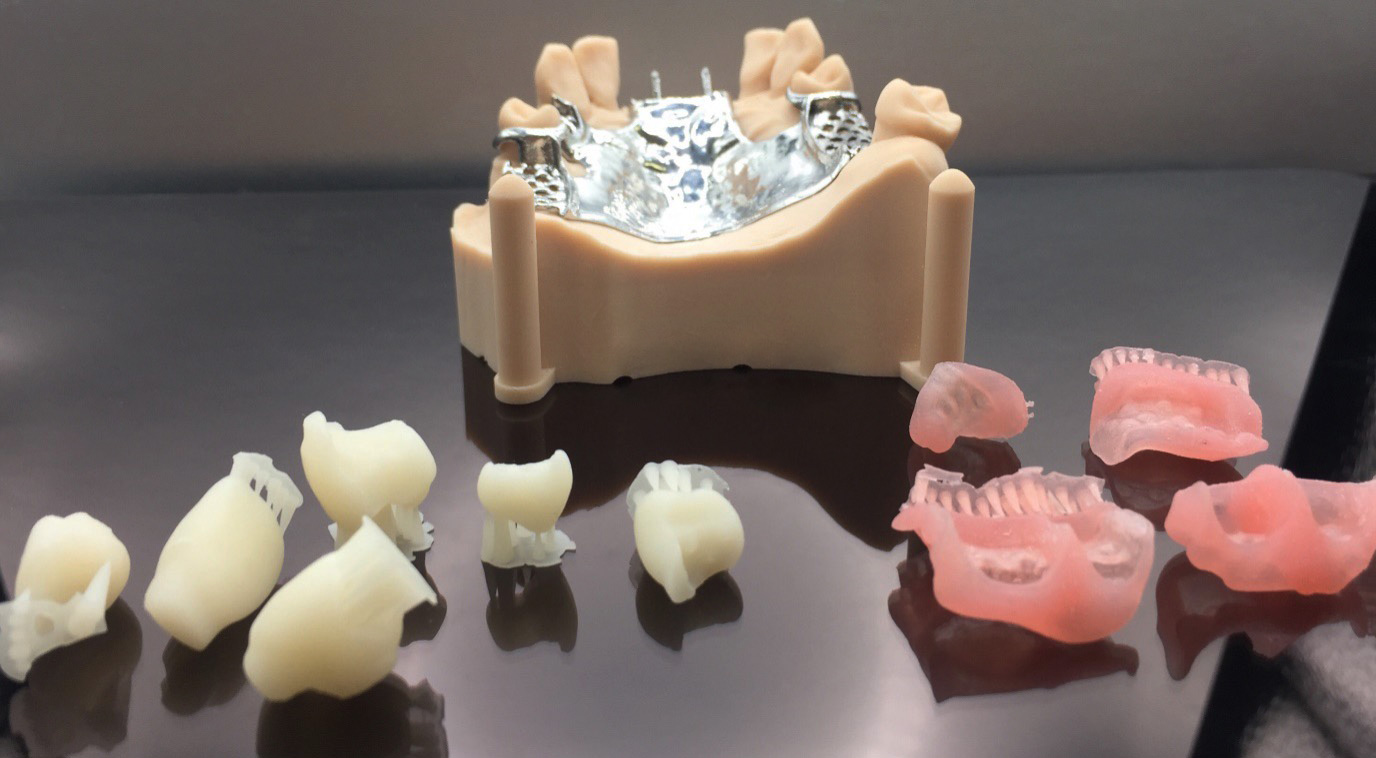

As early adopters GoDigital have embraced the digital workflow for removable prosthetics, including immediate dentures, conversion prostheses for immediate-load implant ‘Teeth in a Day’ cases and full dentures for general long-term wear.

Simple Process...

In addition to a simpler process, the key factor with digital dentures is the reduction of both surgery time and the number of patient visits. It also reduces turnaround time in the laboratory.

The start of this process is to understand the variation in the technique required as this can be both a shorter process and less invasive for the patient.

Digital dentures have changed our workflow dramatically, instead of setting teeth in wax we are spending our time in front of a computer. Our whole production process is so much more efficient with all aspects being 3D printed.

Once this new technique is understood and explained to the patient a digital impression is taken and exported to the lab.

This is done through the GoDigital Labtrac portal which allows you to track the case stages and the pricing structure. Once the scan is sent, we will review and accept it, or if required, request a further scan.

If the scan is accurate then we move on to the bite stage with hard base and wax rim.

If the patient already has usable dentures, you can reline with a silicone wash imp and scan in and export to lab. This way the patient keeps their denture, but we have all the relevant information in the lab.

The Future...

Whilst the process is different to the conventional, we at GoDigital-Dental believe this is the future of denture manufacture giving a repeatable and efficient service for both the dentist and patient.

SEND A MESSAGE

Get in Touch

We will respond to your message as soon as possible.

GoDigital Dental

Contact us to discuss your requirements with an expert.

0115 648 8288

hello@godigital-dental.com

GoDigital Dental Laboratories Ltd

6 Millennium Way West

Nottingham

Nottinghamshire

NG8 6AS

The Lab

Combining technology with our award winning technicians gives the very best quality and consistency our dentists expect. Our digital workflow platform allows our customers to track progress 24/7 and get an instant delivery date at the click of a button.

Supplying you with technology and exceptional levels of training to ensure we are able to deliver consistency every time.

Utilising the latest Digital technology, our platform allows us to reproduce your patient’s dentition through algorithms which accurately copy the patient’s tooth morphology.

All work is completed by qualified and GDC registered dental technicians and our quality control protocols which follow DAMAS, a third party annually audited quality assurance scheme, ensure accuracy every time.